-

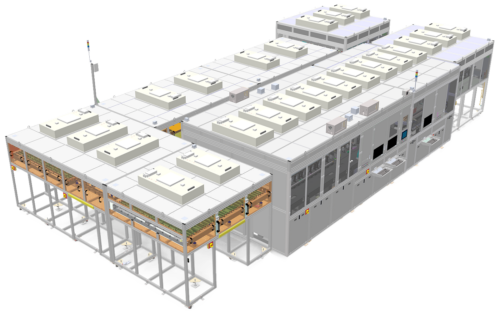

It can be used for Array and CF single substrate, plywood, or thinned substrate products, using special optical systems and inspection logic to detect scratches, surface hillocks or pits, cracks, and foreign materials falling out before and after. Inspections such as drops and contaminations are detected and classified, and combined with the human re-judgment function, effective quality control and filter of products are carried out before shipment.

-

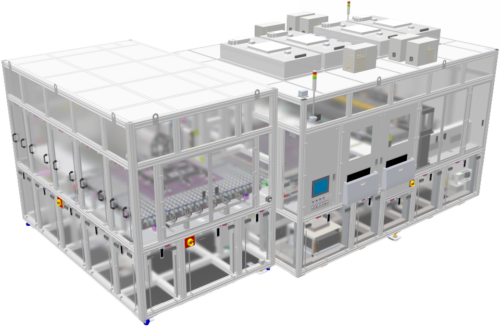

Adopting a high-speed dynamic optical imaging system and stable image quality hardware design, matched with unique inspection algorithm software, it provides accurate defect inspection and classification for high-resolution CF products and fulfills the needs of different customers for product yield improvement and real-time monitoring.

-

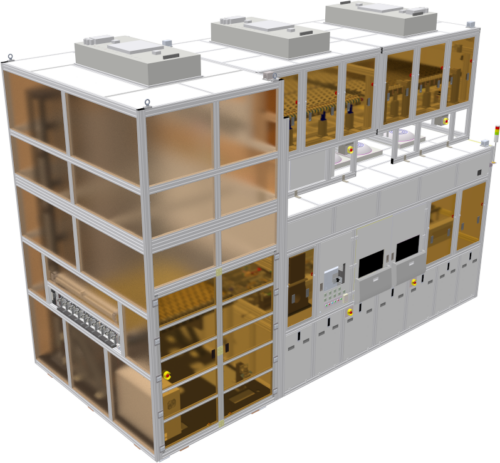

Adapting a variety of optical capturing systems and hardware designs with stable image quality, combined with unique inspection algorithm software, it can effectively inspect, classify, and filter invalid defects of various hole damages and surface abnormal defects generated or remaining after deposition and laser repair. Applied to CMM and FMM products.

-

It provides highly accurate defect inspection and classification for ITO conductive films and circuits, which can be applied to various touch display products and fulfills the needs of different customers for product yield improvement and monitoring.