Touch Panel AOI

✔ Resolution and defect detection capabilities ranging from 1.5μm~5μm

✔ Zero dead zone detection, achieving 100% coverage of the entire panel area

✔ Superior proprietary image inspection technology supporting all sizes and various touch pattern designs

✔ Intelligent defect classification function effectively distinguishes between critical and non-critical defects, improving inspection efficiency

✔ Professional and customized services available

Share:

Applied Field

Touch panel inspection

Features

Indium Tin Oxide (ITO) conductive films and circuits are critical components of touch panels. However, during ITO production, the manufacturing process is prone to defects such as scratches, open circuits, short circuits, and foreign material contamination, which can lead to touch malfunctions in subsequent products.

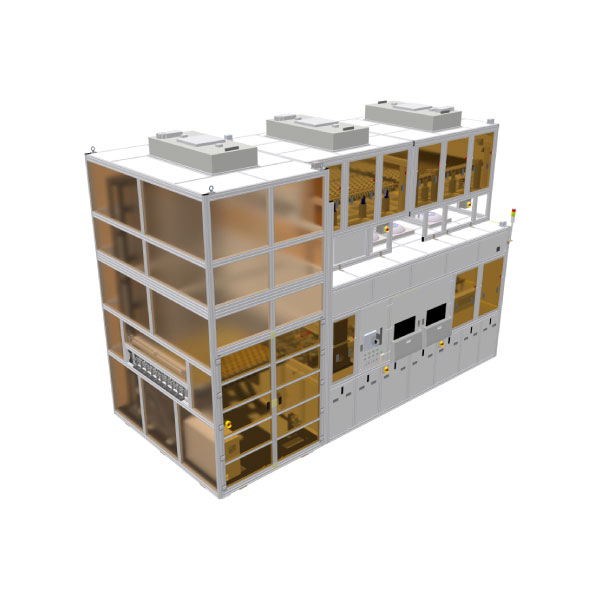

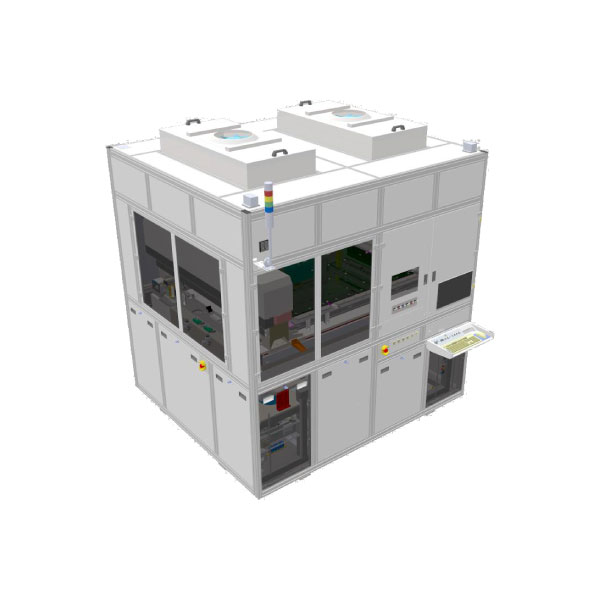

FAVITE’s touch panel automatic optical inspection (AOI) machine provides precise defect detection and classification, effectively improving product yield and reducing production costs.

Features:

✔ Resolution and defect detection capabilities ranging from 1.5μm~5μm

✔ Zero dead zone detection, achieving 100% coverage of the entire panel area

✔ Superior proprietary image inspection technology supporting all sizes and various touch pattern designs

✔ Intelligent defect classification function effectively distinguishes between critical and non-critical defects, improving inspection efficiency

✔ Professional and customized services available

Contact

Error: Contact form not found.