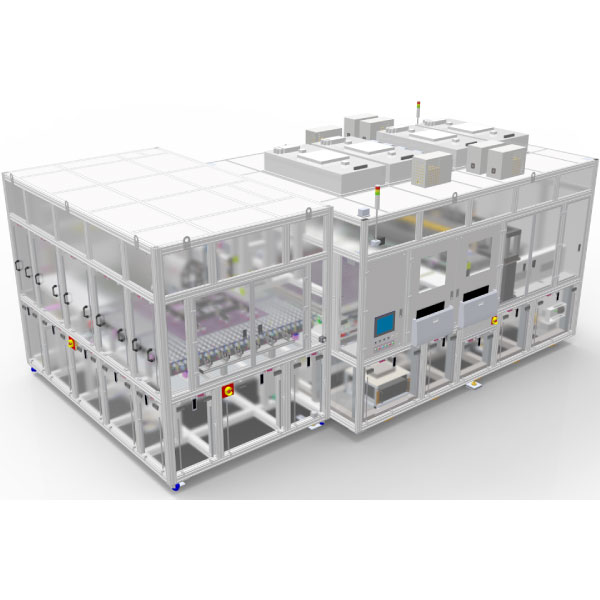

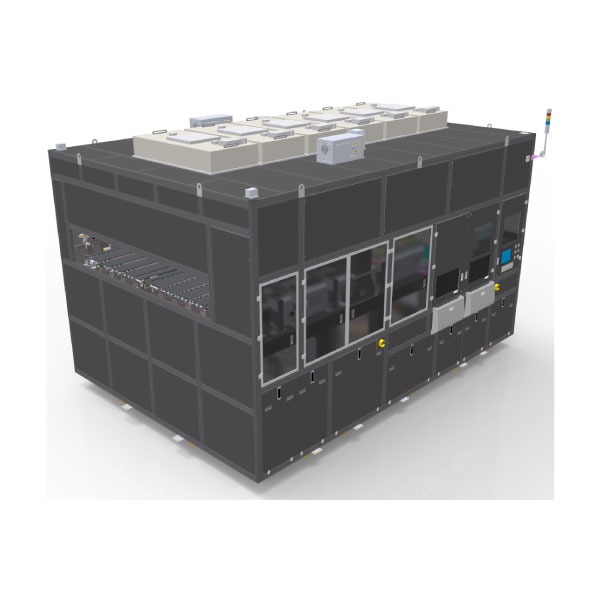

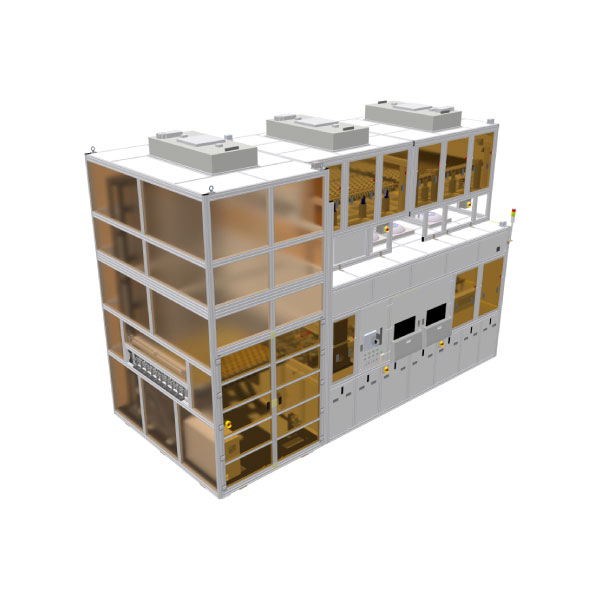

Auto AVI

✔ Resolution and defect detection capabilities ranging from 10μm~100μm

✔ Compatible with pre-cut panel sizes, post-cut substrate sizes from 12″ to 75″, and irregularly shaped products

✔ Detection area covers both the in-plane region and the glass cutting edge simultaneously

✔ Defect classification functionality

Share:

Applied Field

Array or CF (Color Filter) single substrate, laminated panel, or thinned substrate product

Features

Array and Color Filter (CF) single substrates, laminated panels, or thinned substrates are susceptible to defects such as scratches, surface protrusions or depressions, chipping/cracking, foreign material contamination, and stains during processing.

FAVITE’s inspection system utilizes a specialized optical system and detection algorithms to identify and classify defects such as scratches, surface protrusions or depressions, chipping/cracking, foreign material contamination, and stains on pre-cut, post-cut, or thinned substrates. It also incorporates a manual review mechanism to ensure effective quality control and screening of products before shipment.

Features:

✔ Resolution and defect detection capabilities ranging from 10μm~100μm

✔ Compatible with pre-cut panel sizes, post-cut substrate sizes from 12″ to 75″, and irregularly shaped products

✔ Detection area covers both the in-plane region and the glass cutting edge simultaneously

✔ Defect classification functionality

Contact

Error: Contact form not found.