OLED AOI

✔ Resolution and defect detection capabilities ranging from 3μm~5μm

✔ Detection area covers both the mask area and the outer frame area simultaneously, ensuring comprehensive inspection

✔ Inspection technology supports various pattern designs and arbitrarily shaped mask products

✔ Intelligent defect classification function effectively distinguishes between critical and non-critical defects, improving inspection efficiency

Share:

Applied Field

CMM, FMM defect inspection

Features

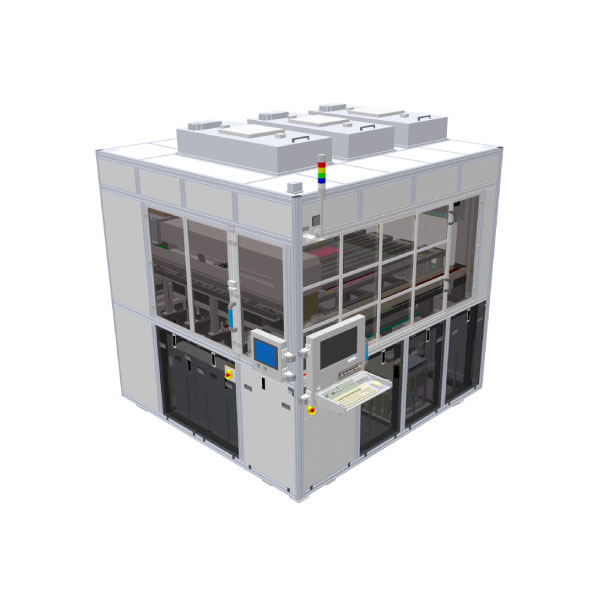

During OLED panel production, the evaporation and laser repair processes can generate or leave behind defects such as pinholes and surface anomalies, including particles, residue, and hole damage. Effective detection, classification, and filtering of non-critical defects are necessary to prevent severe impacts on product quality.

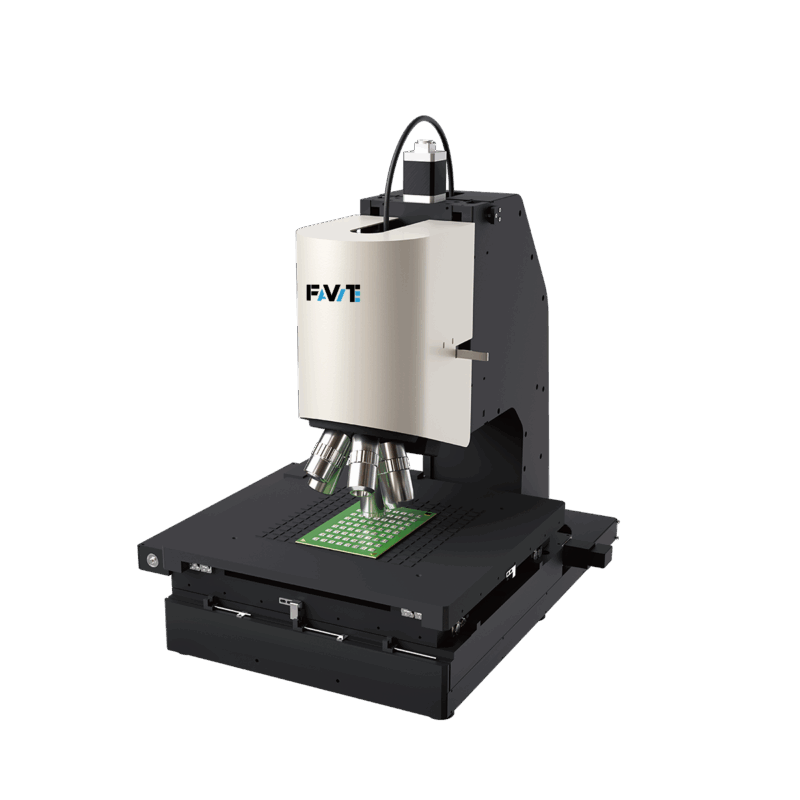

FAVITE’s OLED inspection machine employs multiple optical imaging systems and stable image quality hardware design, along with proprietary detection algorithms, to achieve high-precision defect detection and classification.

Features:

✔ Resolution and defect detection capabilities ranging from 3μm~5μm

✔ Detection area covers both the mask area and the outer frame area simultaneously, ensuring comprehensive inspection

✔ Inspection technology supports various pattern designs and arbitrarily shaped mask products

✔ Intelligent defect classification function effectively distinguishes between critical and non-critical defects, improving inspection efficiency

Contact