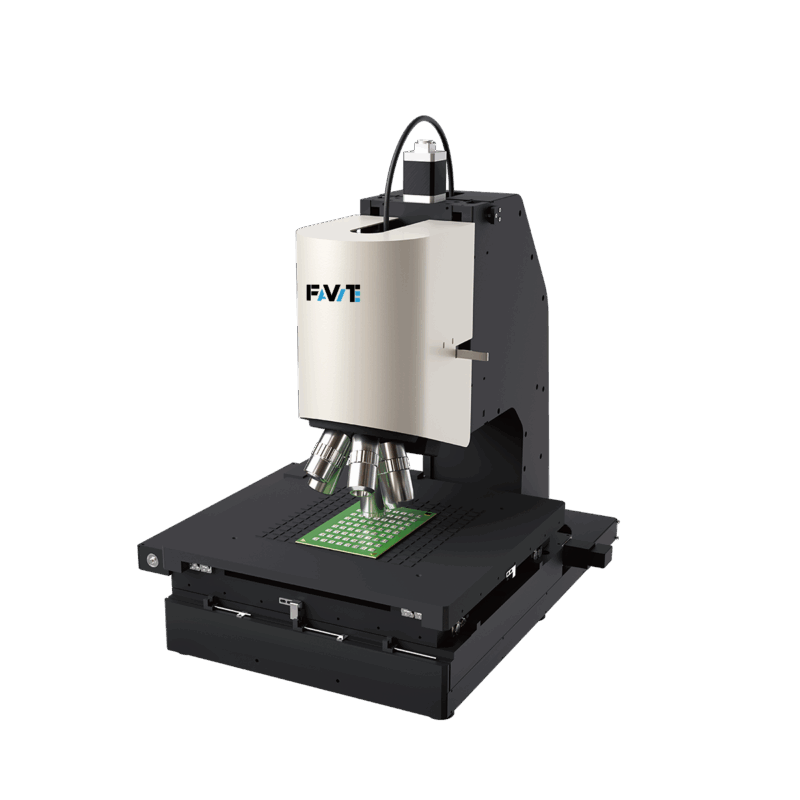

Micro LED COW/COC AOI

✔ COW/COC1: 4″/6″ Wafer Form;

✔ COC2: 200*200mm Panel Form

✔ Detection of various chip defects and missing chips

✔ AI-powered real-time defect classification

✔ Minimum Defect Size: 0.8μm/1μm

✔ Simultaneous high-precision chip TTP/offset/rotation measurement

✔ Can handle chip quantities of 30 million or more

Share:

Applied Field

Micro LED Mass Transfer

Features

In Chip-on-Wafer (COW) and Chip-on-Carrier (COC) processes, due to the extremely small size and vast quantity of Micro LED chips, issues such as multiple chips, missing chips, and other defects can easily occur after transfer. Simultaneously, chips may experience positional shift and rotation after transfer, leading to potential quality problems.

FAVITE’s Micro LED COW/COC inspection and metrology machine can complete full-range defect detection and position measurement of the mass-transferred chips in a short time.

Features:

✔ COW/COC1: 4″/6″ Wafer Form;

✔ COC2: 200*200mm Panel Form

✔ Detection of various chip defects and missing chips

✔ AI-powered real-time defect classification

✔ Minimum Defect Size: 0.8μm/1μm

✔ Simultaneous high-precision chip TTP/offset/rotation measurement

✔ Can handle chip quantities of 30 million or more

Contact

Error: Contact form not found.